Access Network Innovative Technology and Development Project

Guided by the mission of developing supporting technologies to underpin IOWN APN, we are engaged in the development of technologies for smart construction, operation, and maintenance of access network (railway and civil engineering), as well as the development of optical fiber cable and other optical line platform technologies.

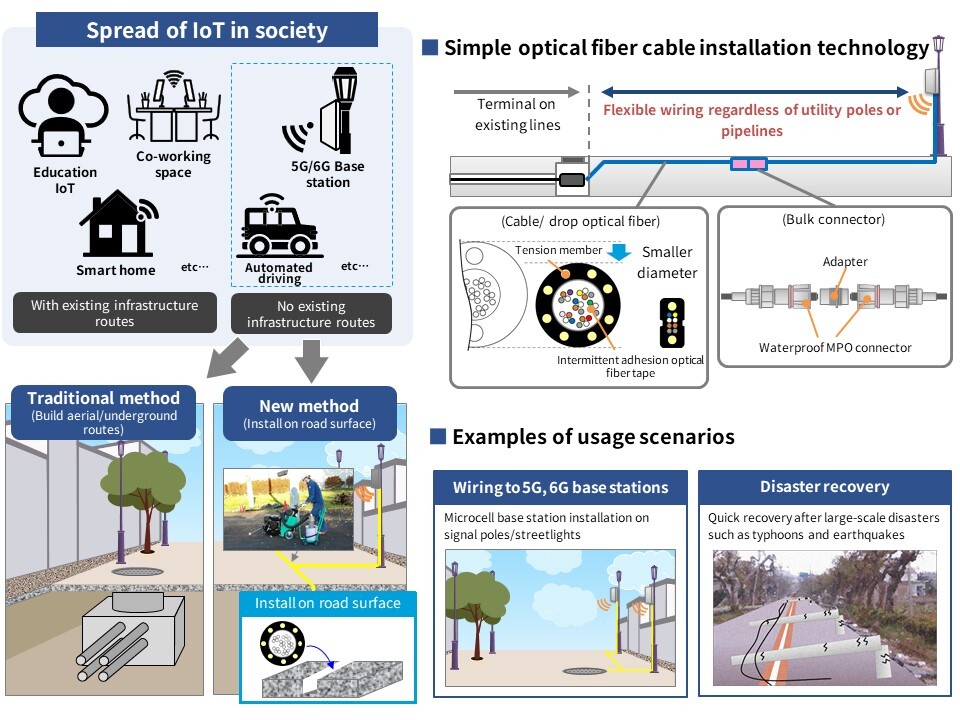

Simple optical fiber cable installation technology

The simple optical fiber cable system installation technology enables the laying of optical fiber cables in sections where new construction of utility poles and pipes cannot be carried out.

The technology features fine fiber optic and drop fiber optic cables with superior elasticity and lateral pressure characteristics that enable installation in narrow grooves on road surfaces, as well as a multi-core bulk connector that simplifies the connection between optical cables.

This will enable comprehensively deploying optical fiber networks across a wide area to realize IOWN APN*1.

*1 APN: All-Photonics Network

Related information

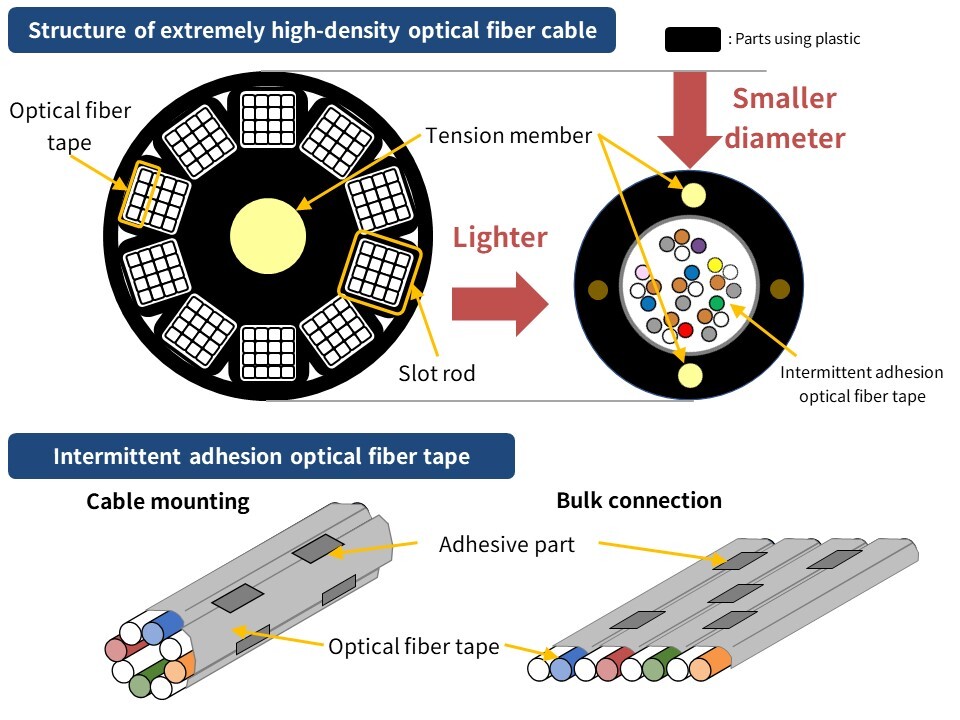

Extremely high-density optical fiber cable technology

The extremely high-density optical fiber cable technology reduces the diameter and increases density of optical fiber cables by uniformly adopting a slot-less optical cable structure, which contributes to improved workability and reduction of environmental impact.

Intermittent adhesion optical fiber tape, which enables high-density mounting and bulk fusion splicing, is applied to achieve smaller diameter and higher density.

This technology makes it possible to install a larger number of core wires in areas where space is limited, enabling efficient construction of optical communication networks.

Related information

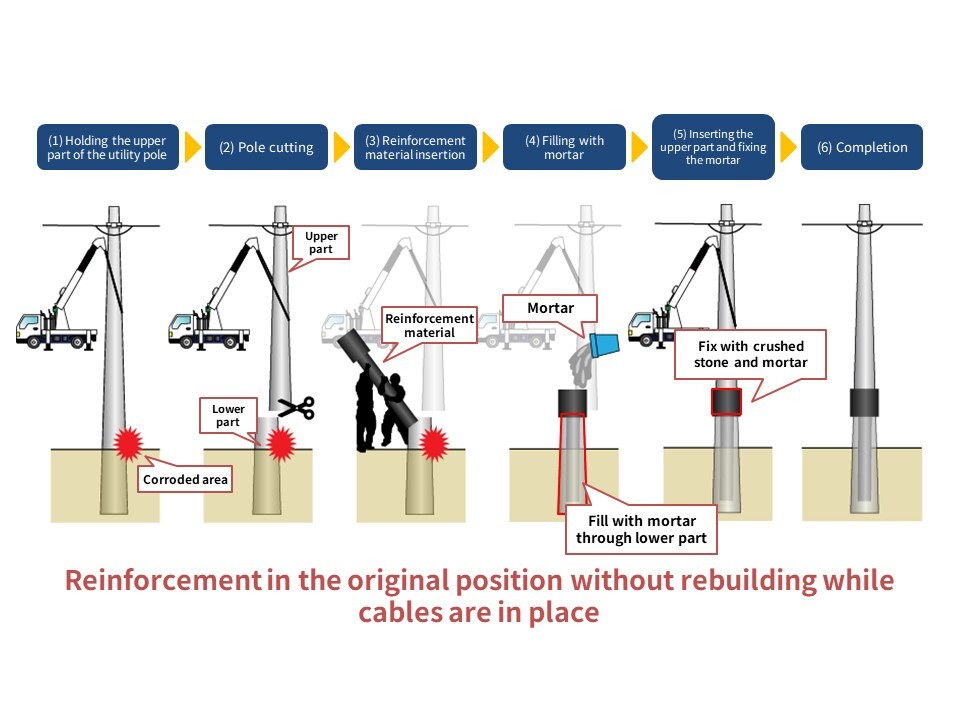

New material utility poles and new construction methods

To realize labor-saving utility pole construction that ensures safety, we are working on the development of new material utility poles and new construction methods (ground reinforcement method).

For the new material utility poles, we are working on the development of lightweight utility poles that have equivalent or higher strength and durability as existing poles for manual pole construction, while utilizing pole analysis simulation technology.

For ground reinforcement methods, we are working to establish a reinforcement method for corroded steel pipe columns that can be completed at the original position without rebuilding while cables are in place, by utilizing core technology related to load calculation.

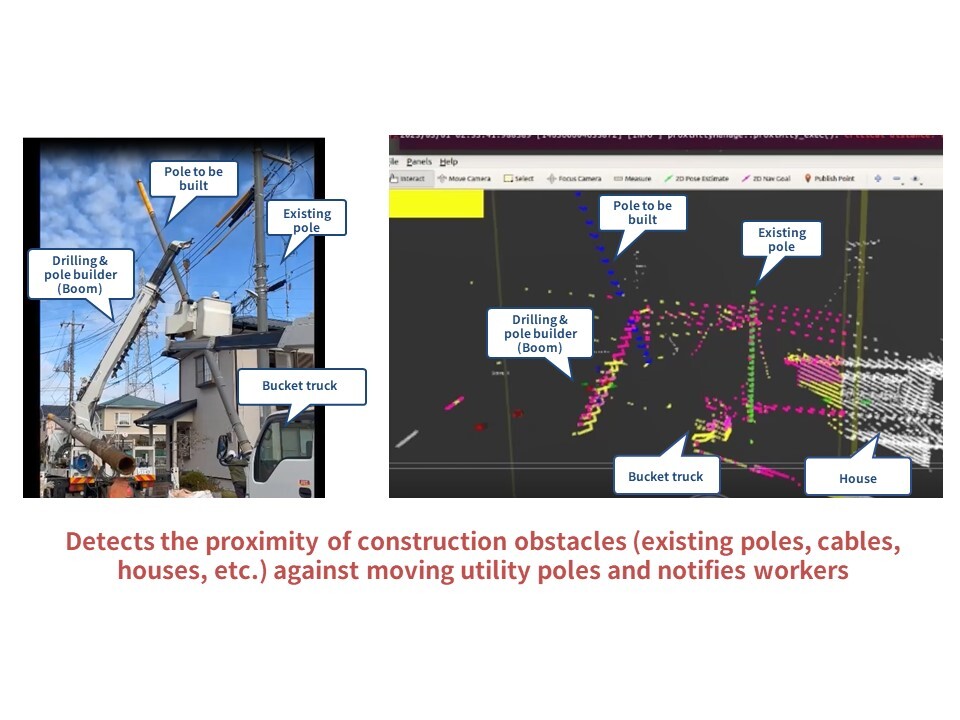

Construction obstacle proximity detection technology

The construction obstacle proximity detection technology accurately detects moving utility poles and construction obstacles and enables real-time distance measurement during construction and pulling of poles.

We developed blind spot countermeasures using multiple sensors and algorithms for ensuring real-time performance and deterring false positives. These enable reducing the preparation time for builders while improving safety by preventing contact accidents.

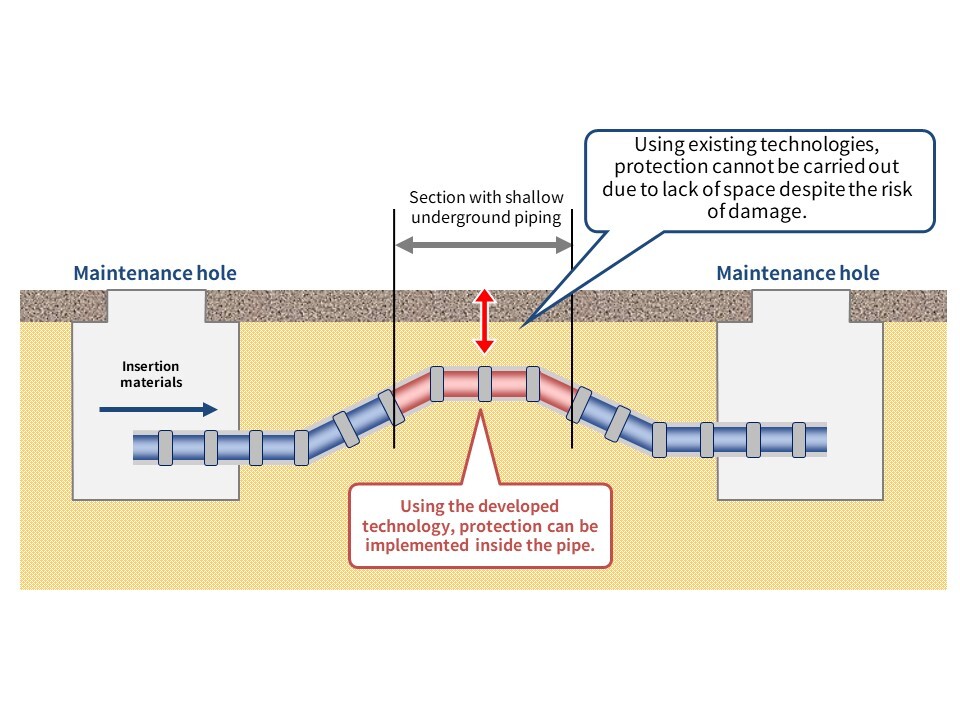

Shallow underground pipeline protection technology

This technology protects sections where pipelines are buried at shallow depth and with insufficient protection, by using the limited space in the pipes without excavation.

The technology combines a force detection function and a visual detection function. The former slows the cutting speed upon contact with the pipe, and the latter causes the operator to notice abnormalities by spattering colored water when the pipe is cut.

By inserting the material having the pipeline protection functions of this technology into an empty pipe, installation can be made without excavation, enabling superior workability and reduction in drilling costs.